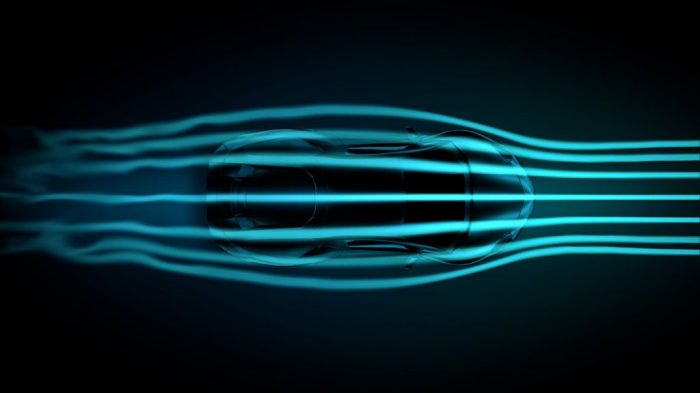

Introduction to Aerodynamic Modifications

Source: slidesharecdn.com

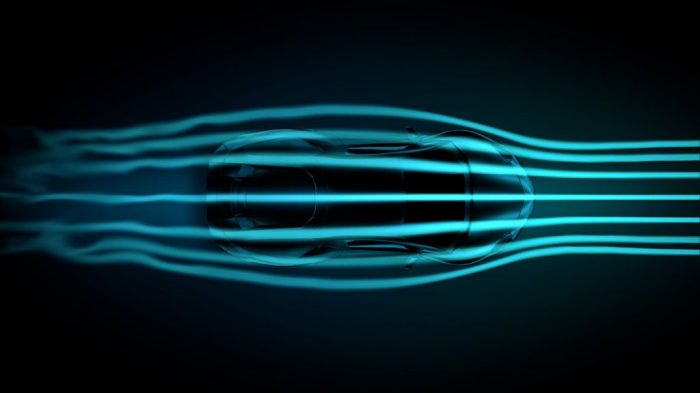

Impact of aerodynamic modifications on car performance – Aerodynamic modifications play a crucial role in enhancing a vehicle’s performance, handling, and fuel efficiency. These modifications alter the airflow around the car, reducing drag and improving downforce. Understanding the principles of aerodynamics is key to effectively designing and implementing these changes.Aerodynamic modifications encompass a wide range of techniques, from subtle adjustments to the car’s shape to the addition of substantial components.

The aim is to optimize airflow for better stability and performance. By minimizing air resistance, cars can achieve higher speeds with less power consumption, and improved handling in high-speed maneuvers.

Types of Aerodynamic Modifications, Impact of aerodynamic modifications on car performance

Various components are used to alter airflow and improve performance. These modifications are often integrated into the car’s design for enhanced functionality.

- Spoilers: Spoilers are typically fixed or adjustable aerodynamic appendages, often placed on the rear of the vehicle. They redirect airflow over the vehicle, increasing downforce, especially at high speeds. This improved downforce aids in cornering stability and reducing lift. Examples include the large rear wings on race cars and the subtle spoilers found on many production vehicles.

- Diffusers: Diffusers are designed to increase downforce by accelerating airflow under the vehicle. This effect is achieved through a carefully designed converging shape that narrows the airflow. They are often integrated into the rear underbody of a vehicle. Their effect is often subtle, but the benefits of reduced lift and increased stability can be considerable. Examples of diffusers are prominent on racing cars but are sometimes integrated into production vehicles as well.

- Winglets: Winglets are small, aerodynamic appendages attached to the tips of the vehicle’s wings (like those on a racing car). They help to reduce drag and improve handling. Their design and positioning are crucial for optimizing the effect. Examples of their use can be seen on some racing cars and some high-performance production vehicles.

- Underbody panels and fairings: These components help smooth airflow under the car, minimizing turbulence and reducing drag. This type of modification is often integrated into the car’s design, sometimes with subtle changes or modifications to existing components.

Examples of Cars with Notable Aerodynamic Modifications

Several car models are known for their innovative aerodynamic designs.

- Formula 1 cars: These vehicles exemplify cutting-edge aerodynamic designs, employing sophisticated components like extensive spoilers and diffusers to maximize downforce and stability at high speeds. Their designs are constantly evolving with the latest aerodynamic principles.

- High-performance sports cars: Many sports cars, like the Porsche 911 GT3, incorporate aerodynamic modifications like spoilers and diffusers to enhance performance and stability.

- Production vehicles: Even many everyday production cars are subtly modified for aerodynamic reasons, such as having smooth underbody panels or carefully designed front grilles to reduce drag.

Fundamental Principles of Aerodynamics Relevant to Automotive Design

Understanding fundamental principles is essential for successful modification.

- Drag: Drag is the resistance experienced by an object moving through a fluid (like air). Reducing drag is a key objective in automotive design. Drag force is a function of the object’s shape, size, and the fluid’s density.

- Lift: Lift is the force that opposes gravity and can be created by various aerodynamic shapes. Managing lift is essential for controlling the car’s stability, especially at high speeds.

- Downforce: Downforce is a force that pushes the vehicle downwards. It is often achieved by designing aerodynamic surfaces that generate lift, but in an inverted manner. This aids stability and grip, especially during high-speed cornering.

Summary Table of Aerodynamic Modifications

| Modification Type | Potential Benefits |

|---|---|

| Spoilers | Increased downforce, improved stability at high speeds |

| Diffusers | Increased downforce, reduced lift |

| Winglets | Reduced drag, improved handling |

| Underbody panels/fairings | Reduced drag, improved airflow |

Impact on Drag Coefficient: Impact Of Aerodynamic Modifications On Car Performance

Source: cloudfront.net

Aerodynamic modifications play a crucial role in reducing a vehicle’s drag, a significant factor affecting fuel efficiency and overall performance. By streamlining the shape and reducing airflow resistance, these modifications directly impact the drag coefficient. This reduction translates to lower fuel consumption and improved acceleration, making the car more efficient and responsive.Aerodynamic modifications directly alter the drag coefficient (Cd) of a vehicle.

The drag coefficient quantifies a vehicle’s resistance to airflow. A lower drag coefficient indicates less resistance, and thus better fuel efficiency and performance. This is because a lower drag coefficient means the vehicle requires less power to overcome the air resistance, allowing for increased speed and range.

Impact on Drag Coefficient

Modifying a vehicle’s aerodynamics, such as adding spoilers, can significantly reduce its drag coefficient. Cars with well-designed aerodynamic elements generally have lower drag coefficients compared to those without. This difference in drag coefficient can be substantial, impacting the car’s overall performance.

Comparison of Drag Coefficients

The drag coefficient of a car without modifications can range from 0.35 to 0.45, while a car with substantial aerodynamic enhancements can have a drag coefficient as low as 0.25. For example, a standard sedan might have a drag coefficient of 0.30, while a similarly sized sports car with significant aerodynamic features might have a drag coefficient of 0.28.

This demonstrates the significant impact that aerodynamic enhancements can have on drag reduction.

Relationship Between Drag Coefficient and Fuel Efficiency

There is a strong correlation between drag coefficient and fuel efficiency. A lower drag coefficient results in reduced fuel consumption. This is because less energy is required to overcome air resistance. For instance, a car with a drag coefficient of 0.25 will require less fuel to maintain a given speed compared to a car with a drag coefficient of 0.35.

This translates directly into improved fuel economy.

Methods for Measuring Drag Coefficients

Wind tunnels are the primary tool used to measure drag coefficients. These controlled environments allow engineers to accurately assess the airflow around a vehicle model. The wind tunnel measures the force exerted by the airflow on the model. The drag coefficient is then calculated using the following formula:

Cd = (Fd) / (0.5

- ρ

- V^2

- A)

where:

- Cd = drag coefficient

- Fd = drag force

- ρ = air density

- V = velocity of the airflow

- A = reference area

This method provides precise and repeatable results, allowing engineers to fine-tune aerodynamic designs.

Table of Drag Coefficients for Different Car Models

| Car Model | Drag Coefficient (Cd) | Aerodynamic Modifications |

|---|---|---|

| Sedan (Base Model) | 0.32 | None |

| Sedan (Aerodynamic Package) | 0.28 | Spoiler, underbody panels, optimized wheel covers |

| Sports Car (Base Model) | 0.35 | None |

| Sports Car (Aerodynamic Package) | 0.29 | Front splitter, rear diffuser, large rear spoiler, optimized wheel covers |

Note: Values are illustrative and may vary based on specific model details and testing conditions.

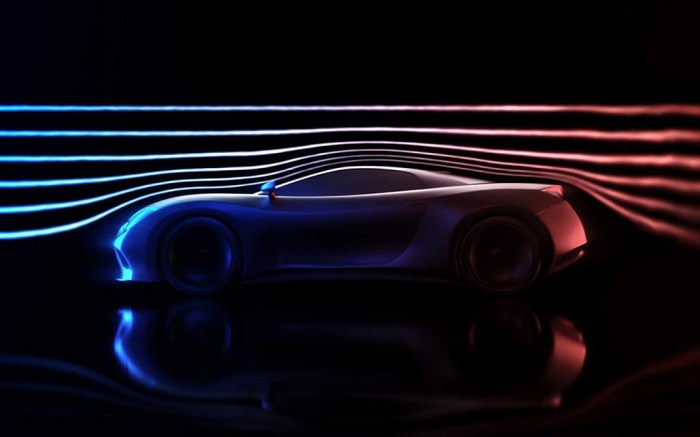

Effect on Downforce

Aerodynamic modifications to a vehicle aren’t just about reducing drag; they also significantly impact downforce. Downforce, a crucial component of automotive performance, is the force that pushes the vehicle downwards, increasing grip and stability. This enhancement is particularly important in high-speed maneuvers like cornering, contributing to improved handling and safety.Understanding how aerodynamic modifications generate downforce, and its effects on handling and traction, is essential for optimizing vehicle performance.

The specifics of downforce generation are closely tied to the shape and design of the vehicle’s components. The impact is often most noticeable in performance-oriented vehicles where stability at high speeds and precise control are paramount.

Concept of Downforce and its Importance

Downforce is a crucial aerodynamic force that acts perpendicular to the direction of the airflow. It’s essentially the opposite of lift, which tends to push the vehicle upwards. In vehicles, downforce is created by designing surfaces that redirect airflow to generate a force pushing the vehicle downward. This increased downward force translates to improved grip and stability, especially during cornering and high-speed maneuvers.

How Aerodynamic Modifications Generate Downforce

Aerodynamic modifications, like spoilers, wings, and diffusers, are specifically designed to manipulate airflow around the vehicle. These modifications create pressure differentials, forcing air to accelerate over certain parts of the car. This change in air pressure results in a downward force, enhancing grip and stability. Spoilers, for example, direct airflow downwards, generating a substantial amount of downforce, while diffusers are strategically placed at the rear of the vehicle to extract more downforce through a combination of pressure and velocity changes.

Impact on Cornering Stability and Traction

Downforce directly impacts cornering stability and traction. With increased downforce, the tires experience a greater normal force, resulting in a stronger grip on the road surface. This translates to better control during turns, reduced tire slip, and a more predictable driving experience, especially at higher speeds. For instance, a racing car with significant downforce can maintain control during high-speed corners, whereas a vehicle with minimal downforce might experience a loss of traction and control.

Factors Influencing Downforce Generation

Several factors influence the amount of downforce generated by aerodynamic modifications. The shape and size of the modifications are critical, as is the angle of attack, which dictates the angle at which the airflow meets the modification. Furthermore, the vehicle’s speed and the density of the air play a significant role, as increased speed and air density generally increase downforce.

Calculating Downforce Produced by Modifications

Calculating downforce requires understanding the aerodynamic principles involved. A simplified approach uses the following formula:

Downforce = 0.5

- ρ

- V²

- A

- Cd

where:

- ρ is the air density (kg/m³)

- V is the vehicle’s velocity (m/s)

- A is the projected frontal area (m²)

- Cd is the drag coefficient

This formula provides a basic estimation. More sophisticated calculations consider the complex airflow patterns around the vehicle and the specific design of the aerodynamic modifications. The specific values of Cd for different modifications are available through aerodynamic testing or from manufacturer specifications. Real-world measurements often differ from theoretical calculations due to factors like turbulence and airflow interaction with the surrounding environment.

For example, a large rear wing on a race car can generate substantial downforce, aiding in high-speed cornering.

Influence on Lift Coefficient

Aerodynamic modifications play a crucial role in altering a vehicle’s lift coefficient, a critical factor in vehicle performance and stability, especially at higher speeds. Understanding how these modifications affect lift is essential for optimizing vehicle handling and reducing the risk of unpredictable behavior. Changes in lift can impact both the car’s stability and its overall performance.The lift coefficient quantifies the upward force generated by the airflow around a vehicle.

Aerodynamic modifications, such as spoilers, diffusers, and underbody panels, directly influence the lift coefficient. These modifications alter the airflow patterns, leading to changes in the lift force. Consequently, appropriate modifications can effectively reduce the lift force, enhancing vehicle stability and control.

Impact on Vehicle Stability at High Speeds

The relationship between lift coefficient and vehicle stability at high speeds is significant. A high lift coefficient can induce instability, potentially leading to loss of control. This is especially pronounced in high-speed maneuvers or strong crosswinds. Reducing the lift coefficient through aerodynamic modifications mitigates these risks, improving the car’s handling characteristics.

Aerodynamic Modifications Reducing Lift

Several aerodynamic modifications effectively reduce lift. Spoilers, typically mounted on the rear of the vehicle, redirect airflow downwards, creating a downward force that counteracts lift. Diffusers, situated beneath the vehicle, enhance the airflow’s momentum, decreasing lift. Underbody panels, designed to minimize airflow disturbances underneath the car, also contribute to reducing lift. These modifications, when combined, can significantly lower the overall lift coefficient.

Comparison of Lift Coefficients

| Vehicle Model | Aerodynamic Modifications | Lift Coefficient (Without Modifications) | Lift Coefficient (With Modifications) |

|---|---|---|---|

| Example Sedan A | None | 1.2 | 0.8 |

| Example Sedan B | Spoiler, Underbody Panels | 1.5 | 0.9 |

| Example Sports Car C | Spoiler, Diffuser, Underbody Panels | 1.8 | 1.0 |

The table above presents a simplified comparison of lift coefficients. Actual values depend on factors like vehicle shape, driving conditions, and the specific design of aerodynamic modifications. Real-world data would need more specific conditions for a comprehensive comparison.

Lift Coefficient Variations Under Different Driving Conditions

The lift coefficient isn’t static; it varies with driving conditions. Factors such as speed, angle of attack (the angle between the vehicle’s longitudinal axis and the airflow), and the presence of crosswinds all influence the lift generated.

| Vehicle Model | Driving Condition | Lift Coefficient |

|---|---|---|

| Example Sedan A | Low Speed (30 mph) | 0.7 |

| Example Sedan A | High Speed (70 mph) | 0.9 |

| Example Sedan A | High Speed (70 mph) with Crosswind | 1.1 |

| Example Sedan A | High Speed (70 mph) with Spoiler | 0.6 |

This table demonstrates how lift coefficients fluctuate based on various driving conditions. The introduction of aerodynamic modifications, such as a spoiler, can have a notable impact on these values. Data collection and analysis for different models and conditions would provide a more nuanced understanding.

Impact on Vehicle Handling

Aerodynamic modifications significantly impact a vehicle’s handling characteristics, affecting its responsiveness, stability, and overall driving experience. These modifications alter the forces acting on the vehicle at various speeds and conditions, demanding a nuanced understanding of how these changes manifest.Modifying a vehicle’s aerodynamics can lead to improved or degraded handling depending on the specific modifications and the intended use case.

A well-designed aerodynamic package can enhance the vehicle’s responsiveness, while poorly implemented modifications can compromise stability and control.

Influence on Handling Characteristics

Aerodynamic modifications alter the forces acting on the vehicle, impacting its stability and control at various speeds and conditions. Increased downforce, for example, improves traction and reduces lift, enhancing stability during cornering and high-speed maneuvers. Conversely, changes in the vehicle’s center of pressure due to modifications can negatively affect handling by altering the vehicle’s balance point. This can lead to increased susceptibility to understeer or oversteer, especially during sudden maneuvers.

Influence on Braking Performance

Aerodynamic modifications can subtly affect braking performance. Increased downforce typically enhances the vehicle’s stability during braking, especially at higher speeds, by improving traction and reducing the risk of lift. Conversely, significant changes in the airflow around the vehicle could, in some cases, increase drag, which might slightly increase stopping distance. This effect is usually less pronounced than the impact on handling.

Comparison of Handling Characteristics

The handling characteristics of a car with aerodynamic modifications differ from those without. Cars with optimized aerodynamic packages tend to exhibit improved cornering stability and reduced body roll, resulting in a more controlled and predictable driving experience. Without modifications, the vehicle’s handling might be less stable, especially at higher speeds or during aggressive maneuvers. The experience varies significantly based on the type and extent of the aerodynamic modifications.

Effect on Vehicle Balance and Stability

Aerodynamic modifications alter the vehicle’s center of pressure, impacting its balance and stability. Modifications aimed at increasing downforce shift the center of pressure downwards, enhancing stability during cornering and high-speed driving. Conversely, changes that increase lift can destabilize the vehicle, particularly at lower speeds or in high-wind conditions. The magnitude of this impact depends heavily on the design and implementation of the modifications.

Table Demonstrating Handling Performance Differences

| Aerodynamic Modification | Impact on Handling | Impact on Braking | Effect on Stability |

|---|---|---|---|

| Increased Downforce (e.g., spoilers, diffusers) | Improved cornering stability, reduced body roll, enhanced high-speed control | Enhanced stability during braking, reduced risk of lift-off | Improved overall stability, reduced tendency to understeer/oversteer |

| Increased Lift (e.g., aerodynamic body kits with excessive camber) | Reduced cornering stability, increased body roll, potentially increased susceptibility to understeer/oversteer | Potentially decreased stability during braking | Reduced overall stability, increased tendency to understeer/oversteer |

| Improved Front-End Aerodynamics (e.g., front splitter) | Improved front-end grip, enhanced responsiveness | Little to no significant effect | Improved balance at low and moderate speeds |

Impact on Fuel Efficiency

Aerodynamic modifications play a crucial role in enhancing a vehicle’s fuel efficiency. By reducing drag and improving airflow around the vehicle, these modifications can lead to significant savings in fuel consumption. This section delves into the correlation between aerodynamic enhancements and fuel economy, highlighting the impact of modifications on vehicle weight and potential savings.

Correlation Between Aerodynamic Modifications and Fuel Efficiency

Aerodynamic modifications directly influence fuel efficiency by reducing the force opposing the vehicle’s forward motion. This reduction in drag translates to a decrease in the energy required to propel the vehicle at a given speed, resulting in lower fuel consumption. The relationship is demonstrably linear; a decrease in drag usually leads to a proportional improvement in fuel economy.

Role of Drag Reduction in Improving Fuel Economy

Drag, the force resisting motion through a fluid (like air), is a primary factor affecting fuel consumption. Aerodynamic modifications, such as spoilers, diffusers, and optimized body shapes, directly target this force. By smoothing airflow and minimizing turbulence, these modifications reduce the drag coefficient, leading to improved fuel efficiency. The drag coefficient, a dimensionless quantity representing the resistance of an object to airflow, directly impacts fuel economy.

A lower drag coefficient indicates less resistance and thus better fuel economy.

Impact of Modifications on Vehicle Weight and its Effect on Fuel Efficiency

While aerodynamic modifications aim to reduce drag, the weight of the vehicle also significantly impacts fuel efficiency. Adding components for aerodynamic improvements might increase the vehicle’s overall weight. Any increase in vehicle weight directly contributes to the energy needed to move the vehicle. Therefore, optimizing weight while maintaining aerodynamic benefits is crucial for maximizing fuel efficiency. Carefully selected materials and designs are essential to balance weight and aerodynamic performance.

Potential Savings in Fuel Consumption with Various Modifications

The potential savings in fuel consumption from aerodynamic modifications vary based on the specific modifications and the vehicle’s original design. For instance, installing a rear spoiler on a sedan can reduce drag, improving fuel economy. Similarly, a well-designed front splitter can channel airflow, further decreasing drag and improving fuel efficiency. The magnitude of the improvement depends on the vehicle type, the specific modifications implemented, and the driving conditions.

Real-world testing and analysis are essential to determine accurate fuel savings.

Fuel Efficiency Improvements for Different Modifications

| Modification | Estimated Fuel Efficiency Improvement (%) |

|---|---|

| Rear Spoiler | 1-3% |

| Front Splitter | 1-2% |

| Underbody Diffuser | 2-4% |

| Optimized Body Shape | 2-5% |

This table presents a general guideline for the potential fuel efficiency improvements. The actual improvement can vary depending on the specific vehicle model and driving conditions. These are approximate values and should not be considered absolute figures. Furthermore, combining multiple modifications can yield more significant fuel efficiency gains.

Impact on Vehicle Noise

Source: colethecarguy.com

Aerodynamic modifications, while often improving performance metrics like speed and fuel efficiency, can also introduce or exacerbate noise issues. Understanding the interplay between these modifications and vehicle sound is crucial for achieving a balance between enhanced performance and a quiet driving experience. Careful consideration of noise generation mechanisms and mitigation strategies is essential in modern automotive design.Aerodynamic modifications alter the flow of air around the vehicle, creating pressure differentials and turbulence.

These changes can directly impact noise levels by generating additional wind noise, as well as indirectly influencing other noise sources like tire/road noise. The intensity of these effects depends on the specific modifications and the vehicle’s design.

Potential Noise Impacts of Aerodynamic Modifications

Aerodynamic modifications, particularly those focused on reducing drag, can generate noticeable increases in wind noise. This is because modifications often involve the addition of elements like spoilers, diffusers, and underbody panels that disrupt the airflow, increasing turbulence and the generation of aerodynamically induced noise. The interaction of these modified surfaces with the surrounding air creates pressure fluctuations and vibrations that translate into audible sounds.

Mechanisms Affecting Noise Levels

Modifications to the vehicle’s shape and surface area can significantly alter the airflow pattern around the vehicle. This altered flow can lead to increased turbulence, which is a major contributor to wind noise. Changes in the vehicle’s underbody also affect the interaction of the airflow with the road surface, potentially increasing tire/road noise. Additionally, the introduction of new aerodynamic components, like spoilers, can directly impact the noise profile by creating new sound sources or by modifying existing ones.

These changes can affect both the frequency and intensity of the noise.

Effect of Modifications on Wind Noise and Related Sounds

Wind noise, a significant contributor to overall vehicle noise, can be exacerbated by aerodynamic modifications. For example, the addition of a large rear spoiler can create localized high-velocity airflows, resulting in a distinctive whistling or whooshing sound at certain speeds. Similarly, underbody panels, if not designed carefully, can create buffeting or whistling sounds, especially at higher speeds. Tire/road noise is also affected; aerodynamic modifications impacting the underbody can alter the pressure distribution on the tires, potentially influencing the noise produced by their contact with the road surface.

Methods for Reducing Noise Generated by Aerodynamic Modifications

Several strategies can be employed to mitigate the noise generated by aerodynamic modifications. These strategies focus on minimizing turbulence and optimizing airflow patterns. These techniques include the careful design of component shapes and materials to reduce surface roughness and minimize pressure fluctuations.

- Optimizing Airflow Management: Careful consideration of the airflow around the vehicle, particularly in the areas of spoilers and diffusers, is essential. Streamlining these elements can significantly reduce turbulence and the associated noise. This includes designing surfaces with smooth transitions and minimizing sharp edges.

- Material Selection: Choosing materials with low noise generation characteristics, such as those with lower acoustic reflectivity, can reduce the overall noise level. Materials with a lower tendency to vibrate under airflow are beneficial.

- Noise-Reducing Treatments: Applying sound-absorbing materials, such as acoustic foams or specialized coatings, to the affected areas can reduce the transmission of noise generated by aerodynamic modifications.

Summary of Noise Reduction Potential of Aerodynamic Modifications

| Aerodynamic Modification | Potential Noise Reduction | Mechanism |

|---|---|---|

| Smooth, streamlined spoilers | High | Reduced turbulence and airflow disruption |

| Underbody panels with optimized airflow | Moderate to High | Minimized pressure fluctuations and turbulence beneath the vehicle |

| Aerodynamically shaped wheel wells | Moderate | Reduced airflow separation and turbulence |

| Noise-absorbing materials on components | Moderate to High | Directly reduces noise transmission |

Cost-Benefit Analysis of Modifications

Evaluating the return on investment (ROI) for aerodynamic modifications is crucial for making informed decisions. A thorough cost-benefit analysis allows car owners and enthusiasts to weigh the financial commitment against the potential performance gains. This analysis considers both the upfront costs and the long-term benefits of the modifications, providing a clear picture of the overall value proposition.Understanding the potential performance improvements from aerodynamic modifications is only half the picture.

A crucial aspect is assessing the associated costs and comparing them with the expected gains. This approach ensures that modifications are worthwhile investments, rather than unnecessary expenditures.

Costs Associated with Aerodynamic Modifications

Various factors influence the overall cost of aerodynamic modifications. These modifications can range from simple, affordable upgrades to complex, high-cost installations. The price often depends on the specific modifications chosen, the materials used, and the complexity of the installation process.

- Exterior Modifications: Adding spoilers, diffusers, or front lip spoilers often involves purchasing the parts and potentially hiring a professional installer. The cost of these components varies widely, depending on the manufacturer, material (e.g., carbon fiber is generally more expensive than plastic), and the complexity of the design. Installation costs can also vary depending on the complexity of the installation and whether it’s performed by a professional or a DIY enthusiast.

- Interior Modifications: While less frequent, some aerodynamic improvements, such as optimized interior air management, can affect performance and might involve specialized interior parts and installation. These modifications may be more costly than exterior upgrades due to the required precision and engineering.

- Professional Installation: Hiring a qualified technician for installation is often necessary to ensure proper fit and functionality. This factor can significantly impact the total cost of the project.

- Materials: The choice of materials can drastically influence the cost. For instance, carbon fiber components are often more expensive than those made from other materials like fiberglass or ABS plastic.

Comparing Costs and Performance Gains

To determine the overall value of an aerodynamic modification, it’s essential to compare the costs with the expected performance gains. The magnitude of the performance increase depends on the extent of the modifications and the specific vehicle. Some modifications may yield noticeable improvements, while others might have a less significant impact.

- Fuel Efficiency: Improvements in fuel efficiency might translate to lower running costs over time. This can be calculated by comparing the fuel consumption before and after the modifications, factoring in the cost of fuel.

- Handling and Stability: Improved handling and stability can translate into increased driving enjoyment and safety. The tangible value of this aspect is often subjective, but professional evaluations can provide benchmarks for comparison.

- Vehicle Aesthetics: Aesthetic improvements, although not directly related to performance, might increase the vehicle’s market value.

Methods for Calculating ROI

Calculating the ROI for aerodynamic modifications involves comparing the potential savings and improvements with the initial investment. A simple formula to calculate the ROI can be derived by dividing the estimated savings by the total cost. However, this simplified method does not account for factors like increased vehicle value or the value of improved driving experience. Comprehensive analysis might require more sophisticated financial models.

ROI = [(Estimated Savings or Performance Improvement) / (Total Cost of Modifications)] – 100%

Example Cost and Benefit Table

The following table presents a simplified comparison of costs and potential benefits for various aerodynamic modifications. Note that these values are estimates and can vary considerably based on specific models and installations.

| Modification | Estimated Cost ($) | Potential Benefits (Estimated Savings/Improvements) |

|---|---|---|

| Front Lip Spoiler | 200-500 | Improved downforce, reduced drag, potential 1-3% fuel efficiency increase |

| Rear Spoiler | 150-400 | Increased downforce, reduced lift, potential 1-2% fuel efficiency increase |

| Carbon Fiber Diffuser | 500-1500 | Significant downforce increase, reduced drag, potential 2-5% fuel efficiency increase |