Introduction to the Relationship

Source: topspeedimages.com

Relationship between car performance and vehicle weight – The performance of a car is intrinsically linked to its weight. Heavier vehicles generally exhibit lower acceleration, slower top speeds, and less responsive braking. This relationship stems from fundamental principles of physics, particularly Newton’s laws of motion, which dictate how force, mass, and acceleration interact. Understanding these relationships is crucial for optimizing vehicle design and predicting performance characteristics.

Fundamental Principles

The fundamental principles governing the relationship between car performance and weight are rooted in Newton’s laws of motion. A heavier vehicle possesses greater inertia, meaning it resists changes in its state of motion more strongly. This resistance translates directly to slower acceleration and lower top speeds, as more force is required to overcome this inertia. Similarly, braking performance is affected as more force is needed to decelerate a heavier mass.

A key principle is that force is equal to mass times acceleration (F=ma). This relationship highlights how changes in mass directly influence the required force to achieve a given acceleration or deceleration.

Performance Metrics

Car performance is evaluated across various metrics. Acceleration, measured in time to reach a specific speed (e.g., 0-60 mph), quantifies the car’s ability to rapidly change its velocity. Top speed, the maximum attainable velocity, reflects the car’s potential for high-speed travel. Braking performance, often measured in stopping distance from a specific speed, indicates the vehicle’s ability to decelerate safely and effectively.

These metrics are directly influenced by the vehicle’s weight.

Factors Contributing to Vehicle Weight

Several factors contribute to a vehicle’s weight. The materials used in construction play a significant role. Heavier materials, such as steel, inherently contribute to higher overall weight. The size and design of the vehicle also affect weight. Larger vehicles typically have more components and structures, leading to increased mass.

Furthermore, the inclusion of advanced safety features, such as reinforced frames and crumple zones, can contribute to a higher overall weight. Lastly, the cargo capacity of the vehicle can also affect its weight. The greater the capacity, the more weight it can carry, thus influencing its performance characteristics.

Performance Metrics and Weight Relationship

| Performance Metric | Weight Impact | Explanation |

|---|---|---|

| Acceleration | Higher weight = slower acceleration | Higher weight requires more force to overcome inertia, resulting in slower acceleration from 0 to a given speed. |

| Top Speed | Higher weight = lower top speed | Greater mass necessitates more power to overcome aerodynamic drag and maintain higher speeds. |

| Braking | Higher weight = longer stopping distance | More force is required to decelerate a heavier vehicle, leading to longer stopping distances. |

| Fuel Efficiency | Higher weight = lower fuel efficiency | Greater mass requires more power to overcome friction and maintain speed, impacting fuel consumption. |

Impact of Weight on Performance Metrics

Vehicle weight significantly influences a car’s performance characteristics. A heavier vehicle requires more energy to accelerate, maintain speed, and stop, leading to noticeable differences in various performance metrics. This section delves into the specific impacts of weight on acceleration, top speed, braking, and handling.Increased vehicle weight directly impacts acceleration, top speed, and braking performance. Heavier vehicles necessitate a more powerful engine to achieve the same acceleration rate as a lighter vehicle.

Consequently, top speed is also affected, as the heavier vehicle will not reach the same maximum speed with the same engine power. Furthermore, heavier vehicles require longer braking distances, necessitating greater stopping power and more effective braking systems.

Impact on Acceleration

Heavier vehicles require more force to overcome inertia and achieve a given acceleration rate. A more powerful engine is needed to compensate for this increased mass, leading to a slower acceleration rate compared to a lighter vehicle with the same engine. For instance, a heavy SUV will take longer to reach 60 mph than a comparable-sized sports car, even with similar engine power.

The greater mass of the SUV directly translates to a slower rate of acceleration.

Impact on Top Speed

The maximum speed a vehicle can attain is also influenced by its weight. While engine power plays a crucial role, the weight of the vehicle acts as a resistance to motion. A heavier vehicle will experience greater air resistance and rolling resistance, limiting its top speed potential. This is evident in the lower top speeds of heavier trucks compared to lighter sports cars.

Impact on Braking

Braking performance is inversely proportional to vehicle weight. Heavier vehicles require longer braking distances to achieve the same level of deceleration as lighter vehicles. This is due to the increased inertia and the need to dissipate the vehicle’s kinetic energy over a longer period. A heavy truck requires significantly more distance to come to a complete stop from a given speed compared to a smaller car.

The additional weight necessitates more powerful brakes and a more effective braking system to compensate for the increased stopping distance.

Influence of Engine Power

Engine power directly affects a vehicle’s ability to overcome the effects of increased weight. A more powerful engine can generate more force, enabling faster acceleration, higher top speeds, and shorter braking distances for a given vehicle weight. The relationship between engine power and vehicle weight is crucial in determining overall performance.

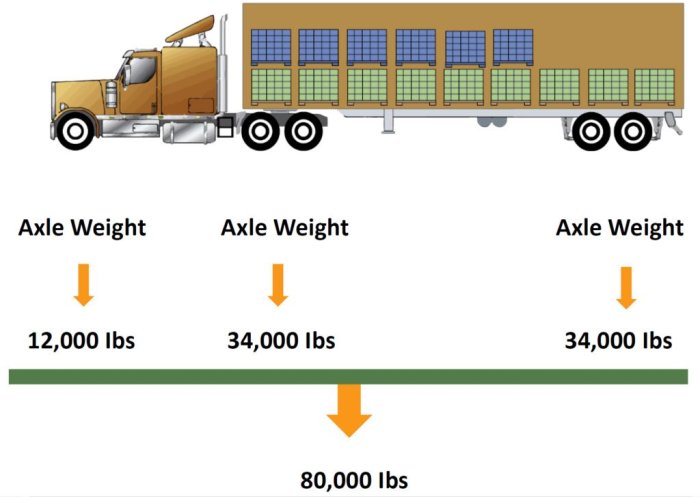

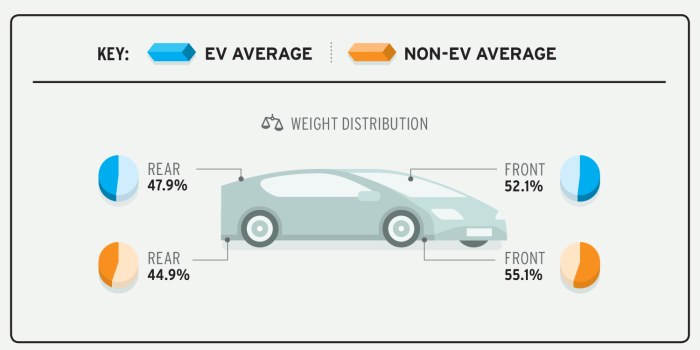

Weight Distribution

Weight distribution significantly impacts handling and stability. A balanced weight distribution across the vehicle’s axles enhances stability and control during cornering and braking. An uneven distribution, where weight is concentrated on one end, can result in poor handling and a tendency to sway or skid. This uneven distribution can be influenced by the placement of the engine, the position of the passengers and cargo, and the distribution of the vehicle’s components.

Impact on Performance Metrics

| Weight Category | Acceleration | Top Speed | Braking |

|---|---|---|---|

| Light | Fast | High | Quick |

| Medium | Moderate | Moderate | Moderate |

| Heavy | Slow | Low | Long |

This table provides a simplified overview of the relationship between weight categories and performance metrics. The specific performance characteristics will vary based on numerous factors, including engine power, tire grip, and aerodynamic design.

Design Considerations and Trade-offs: Relationship Between Car Performance And Vehicle Weight

Source: hearstapps.com

Balancing vehicle performance with weight is a crucial aspect of automotive engineering. Engineers meticulously consider various design choices, materials, and trade-offs to achieve optimal results. This involves navigating a complex interplay between performance requirements, safety standards, and consumer expectations regarding comfort and handling.Automotive designers frequently face a delicate balancing act, as reducing weight often improves performance but can potentially compromise other critical aspects of the vehicle.

Different design approaches must be evaluated in light of the desired performance outcomes and the constraints imposed by regulations and consumer expectations.

Material Selection and Weight Reduction

The choice of materials significantly impacts a vehicle’s overall weight. Lightweight materials offer the potential for performance enhancement, but they must meet stringent safety and durability standards. Different materials exhibit varying properties regarding strength, stiffness, and density, which directly influence a vehicle’s performance characteristics.

- Metals like aluminum and magnesium are increasingly used in automotive construction due to their superior strength-to-weight ratios compared to steel. Aluminum alloys, for example, are commonly employed in body panels, chassis components, and suspension parts. Magnesium, while even lighter, is often used in specific high-performance applications.

- Composite materials, such as carbon fiber reinforced polymers (CFRP), offer exceptional strength and stiffness with remarkably low density. These composites are becoming more prevalent in high-performance vehicles, where weight reduction is critical for achieving enhanced acceleration and handling. The use of CFRP in high-performance sports cars and racing vehicles showcases the significant impact of this technology.

- Advanced manufacturing techniques, such as 3D printing, allow for the creation of complex, lightweight components with intricate designs. This technology enables the design of components that may not be possible with traditional manufacturing methods. Furthermore, it allows for customization and optimization for specific performance requirements.

Trade-offs Between Weight and Other Design Features

Reducing vehicle weight is often pursued in parallel with the enhancement of other critical aspects like safety and comfort. A direct trade-off exists between these features, as lighter components might necessitate stronger materials to meet safety standards, which can impact ride quality and comfort.

- Safety regulations demand a certain level of structural integrity. Therefore, lightweight materials must exhibit sufficient strength to withstand collisions and protect occupants. Safety features like crumple zones and reinforced structural elements are vital for passenger protection, and lightweight materials must complement these features.

- Comfort and ride quality are often inversely proportional to weight reduction efforts. For example, using stiffer materials for reduced weight may result in a harsher ride experience. Engineers often employ sophisticated suspension systems and damping mechanisms to mitigate the impact of reduced weight on passenger comfort.

- Cost considerations play a significant role. Lightweight materials often come at a premium compared to traditional materials. This can impact the overall cost of the vehicle, making cost-effectiveness a significant trade-off in the design process. Balancing cost, performance, and safety is essential.

Methods for Reducing Vehicle Weight

Various methods exist for reducing vehicle weight without compromising safety or performance. These methods include material selection, optimized component design, and innovative manufacturing techniques.

- Optimization of component design involves meticulously analyzing the stress and load distribution on each component. This process enables the design of components that are both strong and lightweight. Modern computer-aided design (CAD) tools are crucial in optimizing component design for minimal weight without compromising performance.

- Implementing advanced manufacturing techniques, like high-strength steel alloys, can reduce weight without compromising safety or durability. For example, the use of high-strength steel in vehicle frames reduces the overall weight while maintaining the required strength for structural integrity.

- Minimizing unnecessary components and using hollowed-out or optimized shapes can lead to significant weight reduction. Examples include designing more efficient exhaust systems or employing lightweight, aerodynamic wheel designs.

Examples of Lightweight Materials and Technologies

The automotive industry continuously explores and implements novel lightweight materials and technologies. These advancements allow for a better balance between weight, performance, and safety.

- High-strength steel alloys, often with advanced manufacturing techniques, are used in chassis components. The use of these materials leads to substantial weight reduction without compromising the structural integrity of the vehicle.

- Aluminum alloys are widely used in body panels and chassis components, reducing the overall weight and enhancing fuel efficiency. Their increased usage in contemporary vehicle construction demonstrates the effectiveness of aluminum in weight reduction.

- Carbon fiber composites are utilized in high-performance vehicles to achieve significant weight reduction. Their use enhances performance and acceleration while maintaining structural integrity.

Historical Trends and Technological Advancements

The relationship between a car’s performance and its weight has undergone significant evolution throughout automotive history. Early vehicles often prioritized sheer power and ruggedness over efficiency, leading to substantial vehicle weights. Modern vehicles, however, increasingly prioritize fuel efficiency and handling, driving a continuous push toward weight reduction. This evolution is deeply intertwined with advancements in engine technology, materials science, and aerodynamic design.

Evolution of the Weight-Performance Relationship

The historical trend shows a clear shift from prioritizing brute force to optimizing for both performance and efficiency. Early automobiles, often built with heavier materials and less sophisticated designs, sacrificed fuel economy and handling agility for raw power. This contrasts sharply with the modern emphasis on lightweight materials, optimized engine configurations, and aerodynamic design. This shift reflects a broader societal trend towards sustainability and performance enhancements.

Impact of Engine Technology

Advancements in engine technology have significantly influenced the weight-performance dynamic. The transition from large, heavy gasoline engines to smaller, more efficient engines, along with the rise of hybrid and electric powertrains, has been crucial in reducing vehicle weight. Downsizing engines allows for lighter components while maintaining or improving performance. The adoption of lightweight materials, such as aluminum and carbon fiber, in engine components further enhances this trend.

Role of Materials Science

Materials science plays a pivotal role in reducing vehicle weight without compromising structural integrity. The development of high-strength, lightweight alloys has enabled engineers to create stronger components while simultaneously decreasing mass. Examples include the use of aluminum in body panels and high-strength steel in chassis structures. The application of composite materials, like carbon fiber, in body panels and other components, further contributes to significant weight reductions.

Aerodynamics in Weight Reduction

Aerodynamic design has become an increasingly important factor in reducing the impact of weight on performance. By minimizing drag, aerodynamic improvements allow vehicles to achieve higher speeds with less engine effort, leading to enhanced fuel economy and performance. The use of streamlined shapes, optimized air intakes, and active aerodynamic elements further contribute to minimizing the detrimental effect of vehicle weight on performance metrics.

Modern cars incorporate complex computational fluid dynamics (CFD) to optimize aerodynamic performance.

Historical Vehicle Examples and Performance

The 1950s saw the rise of large, heavy American cars, epitomized by vehicles like the Cadillac and Chevrolet. These vehicles often featured powerful V8 engines but were significantly heavier than their modern counterparts, which often resulted in reduced fuel efficiency and handling. In contrast, the rise of Japanese manufacturers in the late 20th century, such as Honda and Toyota, brought lighter vehicles that prioritized fuel efficiency and handling agility.

Summary of Historical Trends

| Era | Average Vehicle Weight | Average Performance Metrics | Explanation |

|---|---|---|---|

| 1950s | High | Lower | Larger, heavier vehicles with powerful engines, sacrificing fuel economy and handling. |

| 1970s-1980s | Moderate | Moderate | Introduction of smaller engines and fuel efficiency improvements. |

| 1990s-2000s | Moderate to Low | High | Focus on lightweight materials, aerodynamic design, and engine downsizing. |

| 2010s-Present | Low | High | Continued focus on lightweight materials, efficient powertrains (including hybrids and EVs), and advanced aerodynamics. |

Practical Applications and Real-World Examples

Source: 3horsestrailer.com

Understanding the relationship between vehicle weight and performance is crucial for the automotive industry. Optimizing this relationship allows engineers to create vehicles that are both efficient and engaging to drive. This knowledge also significantly impacts fuel economy, influencing consumer choices and the overall environmental impact of transportation.A lighter vehicle generally translates to better acceleration, handling, and braking performance.

Conversely, a heavier vehicle might sacrifice these attributes for increased safety and cargo capacity. This trade-off is a key design consideration for manufacturers.

Importance in the Automotive Industry

The automotive industry heavily relies on understanding the weight-performance relationship. Engineers use this understanding to fine-tune designs, optimize materials, and ultimately create vehicles that meet specific performance goals. Accurate weight estimations are vital for calculating center of gravity, influencing stability and handling characteristics. The ability to precisely predict performance based on weight enables manufacturers to ensure that their vehicles meet safety standards and consumer expectations.

Real-World Examples of Vehicles with Varying Weights and Performance Characteristics

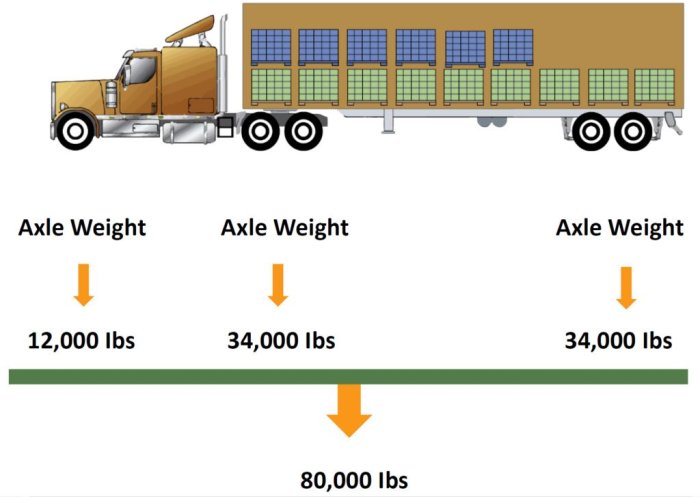

Numerous examples illustrate the impact of weight on performance. A sports car like the Porsche 911, known for its light weight and high-performance capabilities, demonstrates the positive correlation between low weight and high performance. Conversely, a heavy-duty truck like a Freightliner, designed for hauling heavy loads, prioritizes cargo capacity over speed and agility. The weight distribution of the vehicle is also a crucial factor for stability and maneuverability.

Weight Influence on Vehicle Fuel Efficiency

A heavier vehicle requires more energy to accelerate and maintain speed. This increased energy demand directly translates into reduced fuel efficiency. The extra weight adds drag, requiring the engine to work harder, thus consuming more fuel. Lightweight vehicles, on the other hand, generally offer better fuel economy. This is a key factor in vehicle design, particularly for mass-produced vehicles, and manufacturers constantly strive for optimal weight-to-performance ratios.

Designing Efficient and Powerful Vehicles, Relationship between car performance and vehicle weight

A profound understanding of the weight-performance relationship helps engineers design vehicles that are both efficient and powerful. The optimization of weight distribution is crucial for handling, stability, and fuel efficiency. By reducing unnecessary weight without compromising structural integrity, engineers can enhance performance characteristics. Employing lightweight materials like carbon fiber or advanced alloys is crucial in this endeavor.

Table of Vehicle Types and Performance Characteristics

| Vehicle Type | Weight | Performance | Example |

|---|---|---|---|

| Sports Car | Light | High Performance | Porsche 911 |

| SUV | Medium | Moderate Performance, Variable Fuel Efficiency | Toyota RAV4 |

| Truck | Heavy | Low Acceleration, High Payload Capacity | Freightliner Cascadia |

| Motorcycle | Light | High Performance, High Fuel Efficiency | Ducati Panigale |

| Minivan | Medium | Moderate Performance, Moderate Fuel Efficiency | Honda Odyssey |

Future Implications and Emerging Technologies

The relationship between vehicle weight and performance is constantly evolving, driven by technological advancements and shifting consumer demands. Future developments promise significant changes, impacting not only performance but also safety, sustainability, and the overall driving experience. Understanding these trends is crucial for anticipating the future landscape of automotive engineering.

Potential Advancements in Weight Reduction Technologies

Current weight reduction techniques, such as using lightweight materials like carbon fiber and aluminum alloys, are already significantly impacting vehicle design. Future innovations will likely focus on even more sophisticated material science, potentially leading to the development of novel composites with enhanced strength-to-weight ratios. Additive manufacturing (3D printing) holds promise for creating complex, lightweight components tailored to specific vehicle designs.

This personalized approach could optimize weight distribution and reduce overall vehicle mass. Moreover, advancements in manufacturing processes could streamline production and reduce material waste, further contributing to weight reduction.

Role of Electric Vehicles in Weight-Performance Dynamics

Electric vehicles (EVs) are influencing the weight-performance relationship in several ways. The absence of a heavy internal combustion engine (ICE) allows for significant weight reduction, enabling EVs to achieve comparable or superior performance figures to their gasoline-powered counterparts. However, battery packs, while crucial for EV functionality, can be substantial, creating a trade-off between weight and range. Future advancements in battery technology, such as solid-state batteries, are expected to deliver higher energy density with reduced weight, potentially further enhancing EV performance and range.

The weight of battery packs is a crucial consideration, influencing not only acceleration and top speed but also handling characteristics and braking performance.

Impact of Autonomous Driving on Vehicle Design

Autonomous driving technologies will introduce new design considerations for vehicle weight and structure. Autonomous vehicles often require sophisticated sensors, processors, and complex software systems, adding to the overall weight. However, the potential for simplified vehicle architectures and reduced need for safety features (such as traditional braking systems) could lead to significant weight savings. The optimization of the vehicle’s structure to support autonomous driving functions will also play a crucial role.

Emerging Technologies for Weight Reduction

Several emerging technologies hold the potential to reduce vehicle weight without compromising safety or comfort. One such area is the exploration of novel materials with superior strength-to-weight ratios, like graphene-based composites. Advanced manufacturing processes, such as those based on selective laser melting, can produce complex geometries with intricate designs, leading to optimized weight distribution. Moreover, the use of recycled and sustainable materials can contribute to environmental consciousness and weight reduction.

Potential Future Technologies Impacting Weight-Performance Relationship

- Advanced Composites: Continued development of advanced composites with higher strength-to-weight ratios, enabling lighter and more robust vehicle structures. Examples include carbon fiber-reinforced polymers (CFRP) and other innovative materials.

- Optimized Battery Technology: The development of solid-state batteries with enhanced energy density and reduced weight, significantly impacting the weight-range trade-off for electric vehicles.

- Lightweight Manufacturing Techniques: Innovations in manufacturing processes like additive manufacturing (3D printing) for creating complex, lightweight components tailored to specific vehicle designs. This could significantly reduce material waste and increase production efficiency.

- Autonomous Driving System Optimization: Reducing the weight of autonomous driving systems by optimizing sensor placement, improving software efficiency, and potentially reducing the need for redundant safety features.

- Sustainable Materials: Utilization of recycled and sustainable materials in vehicle construction, which can simultaneously reduce weight and environmental impact. This includes the use of bio-based polymers.